Tarmac 6

The Specialized Tarmac is for serious road cyclists prioritizing performance, speed, and efficiency. Whether racing or training, these riders want a lightweight, high-quality bike that helps them perform at their best. But with bikes across the market starting to look alike, our goal was to showcase the advanced technology in the latest Tarmac and make it simple to explain on the sales floor.

PROJECT SUMMARY

Client: Specialized Bicycles

Specialized Bicycles is a leading brand that designs high-performance bikes and gear, focusing on innovation, quality, and meeting the needs of riders across various cycling disciplines.

Responsibilities:

Campaign strategy

Research

Art and creative direction

Scriptwriting and copywriting

-

Customers can't see the key technologies that make the Tarmac perform well. Technologies critical to the bike's handling and performance, like Rider-First Engineering (Composite technology) and Wintunnel Engineered (Aerodynamics tuning), are part of the development process rather than a specific feature that is easy to call out while speaking to a customer. This makes it difficult for salespeople to explain the bike's value compared to other bikes that don't have the same level of development but share a similar look.

-

Data Analysis:

We surveyed 150 global dealers to learn how they explain the Tarmac's key technologies to customers. The results showed two main issues: dealers explained the technology inconsistently, and sales teams didn't have visuals to support their explanations.

Product Focus:

While the campaign focused on the Tarmac, other models soon used similar technology. So, we decided to highlight the technology itself rather than just the Tarmac platform.

Sales Training:

Based on our research, we created training materials to help sales teams and dealers understand the technology better. We tracked training completion through our existing platform and offered incentives, like free in-store displays, to encourage participation.

Retail Displays:

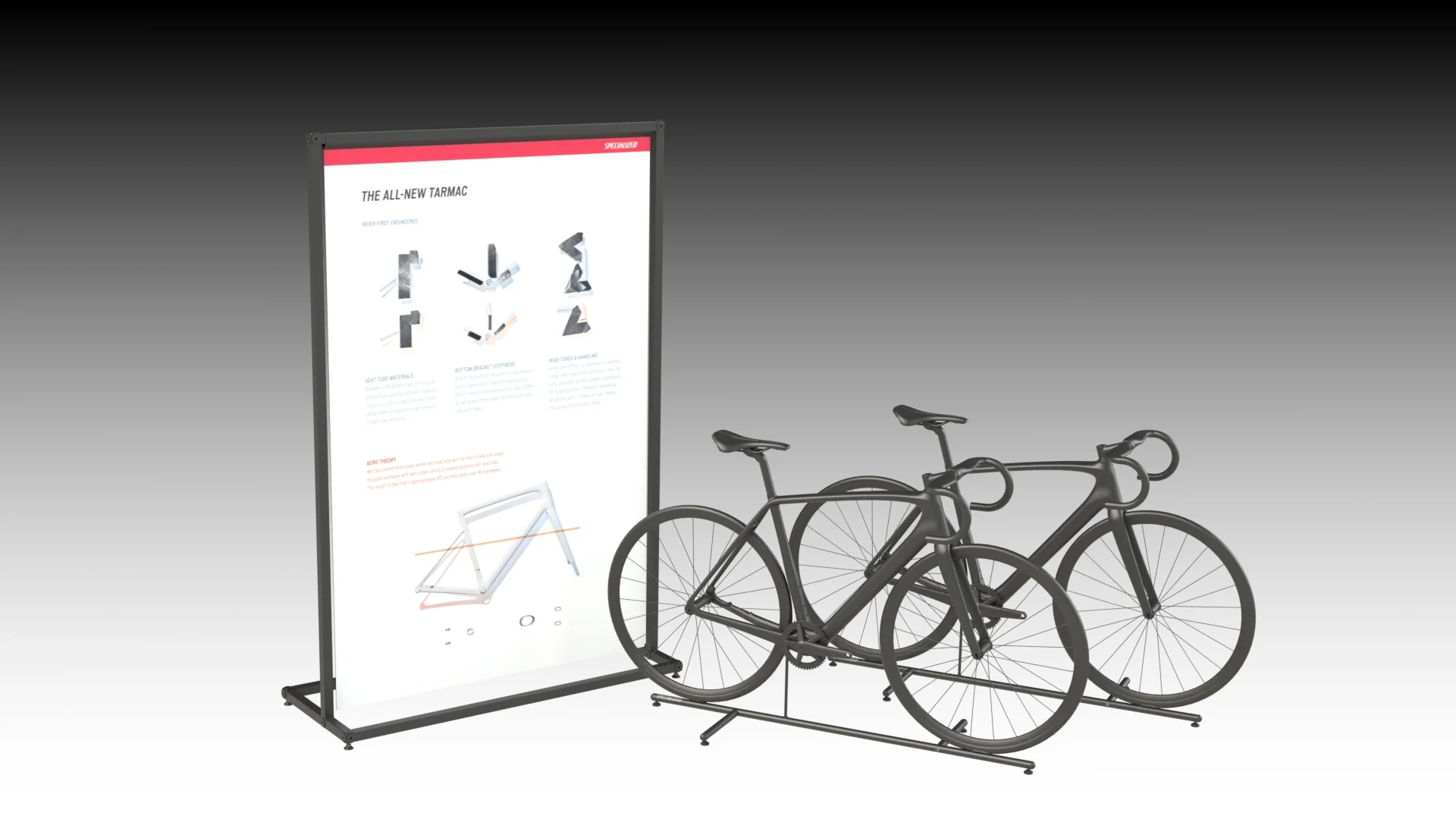

Retail displays were a key part of the campaign. Dealers who completed the training could receive free displays, designed to fit different store sizes and budgets. These displays used large images to make it easier for sales staff to explain the technology to customers.

Campaign Rollout:

We rolled out the campaign in three steps. First, we launched it through our training platform, SBCU, which tracks training completion. Next, we introduced retail displays to key stores, helping them use the materials in their sales pitches. Finally, we offered the displays to all interested dealers and launched a digital version for customers to view online.

-

We surveyed a group of the original dealers after they received the training and displays. Over 90% were able to explain the technology in line with our materials, more than 50% up from the initial research sample.

Rider-First Engineered™

Simply put, Rider-First Engineering is Specialized's development process for ensuring that each bicycle size provides the same user experience.

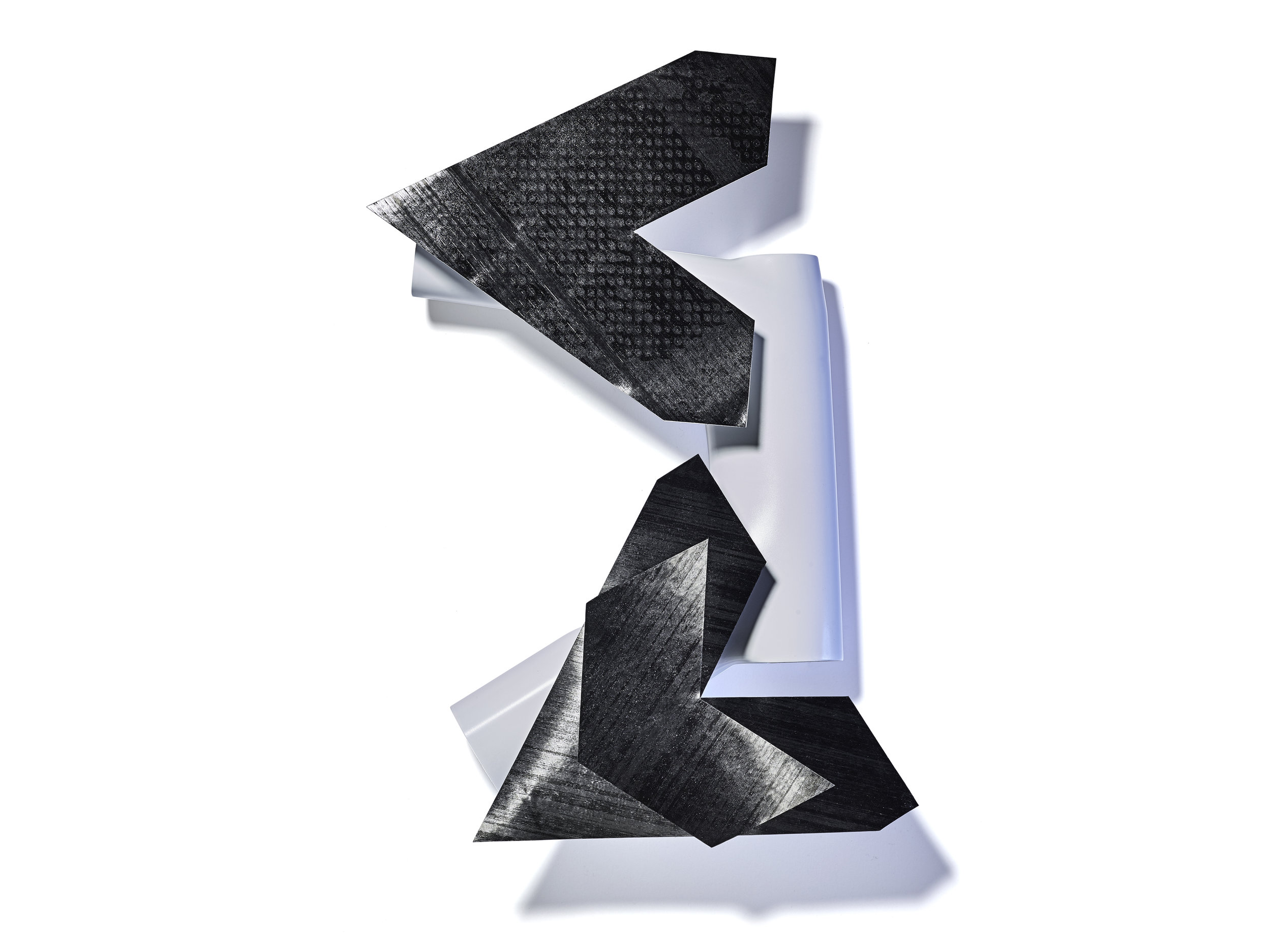

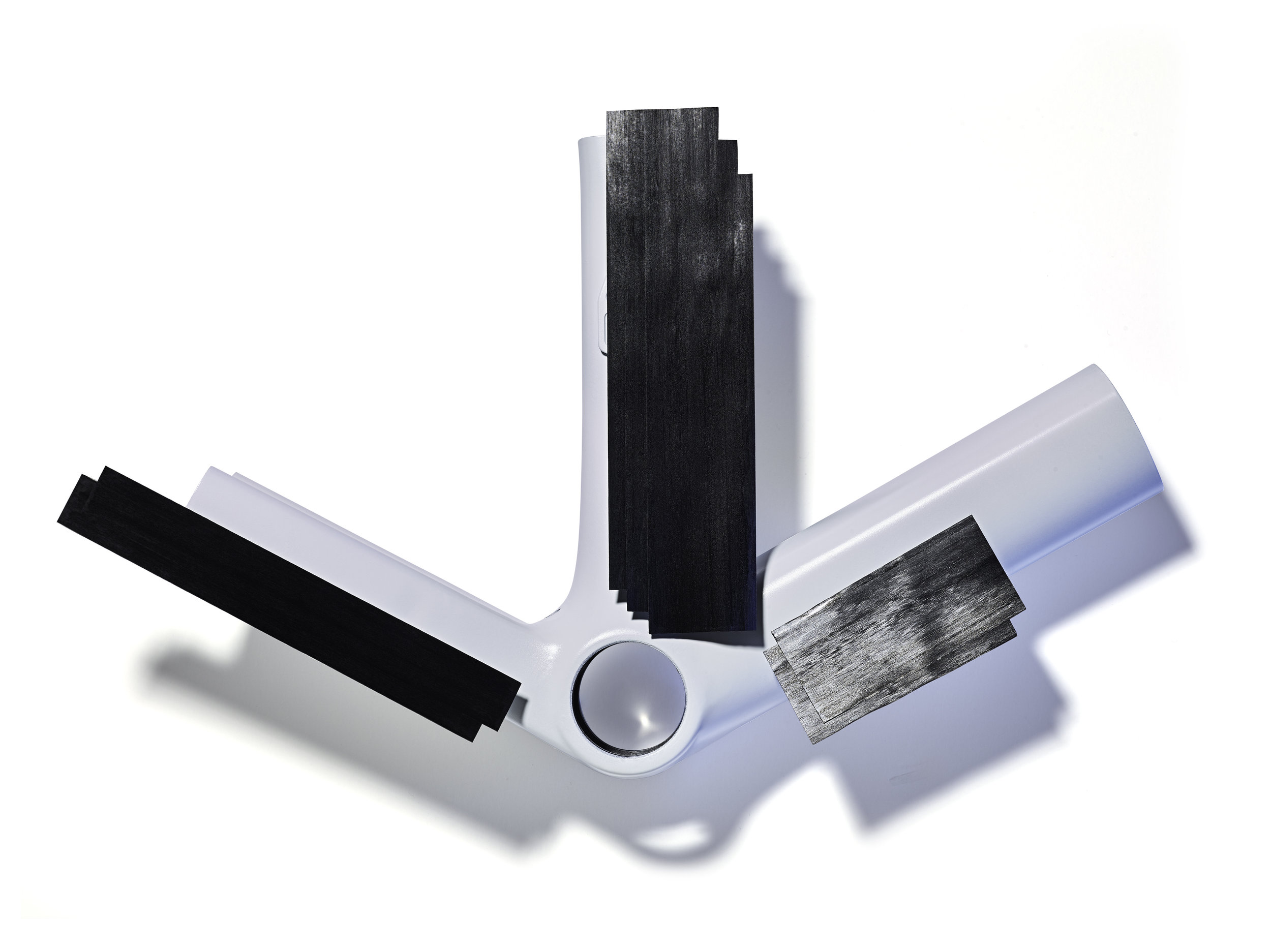

As a bicycle frame increases and the rider becomes taller or heavier, the bike's stiffness targets must change to deliver the exact handling and pedaling characteristics throughout the size range. To do this, Specialized's engineers have developed a series of lab and real-world tests that measure feedback to the rider at various points on the bike frame. Each of the seven frame sizes is then tested, and its carbon fiber layup is adjusted until all products hit the same standard for performance.

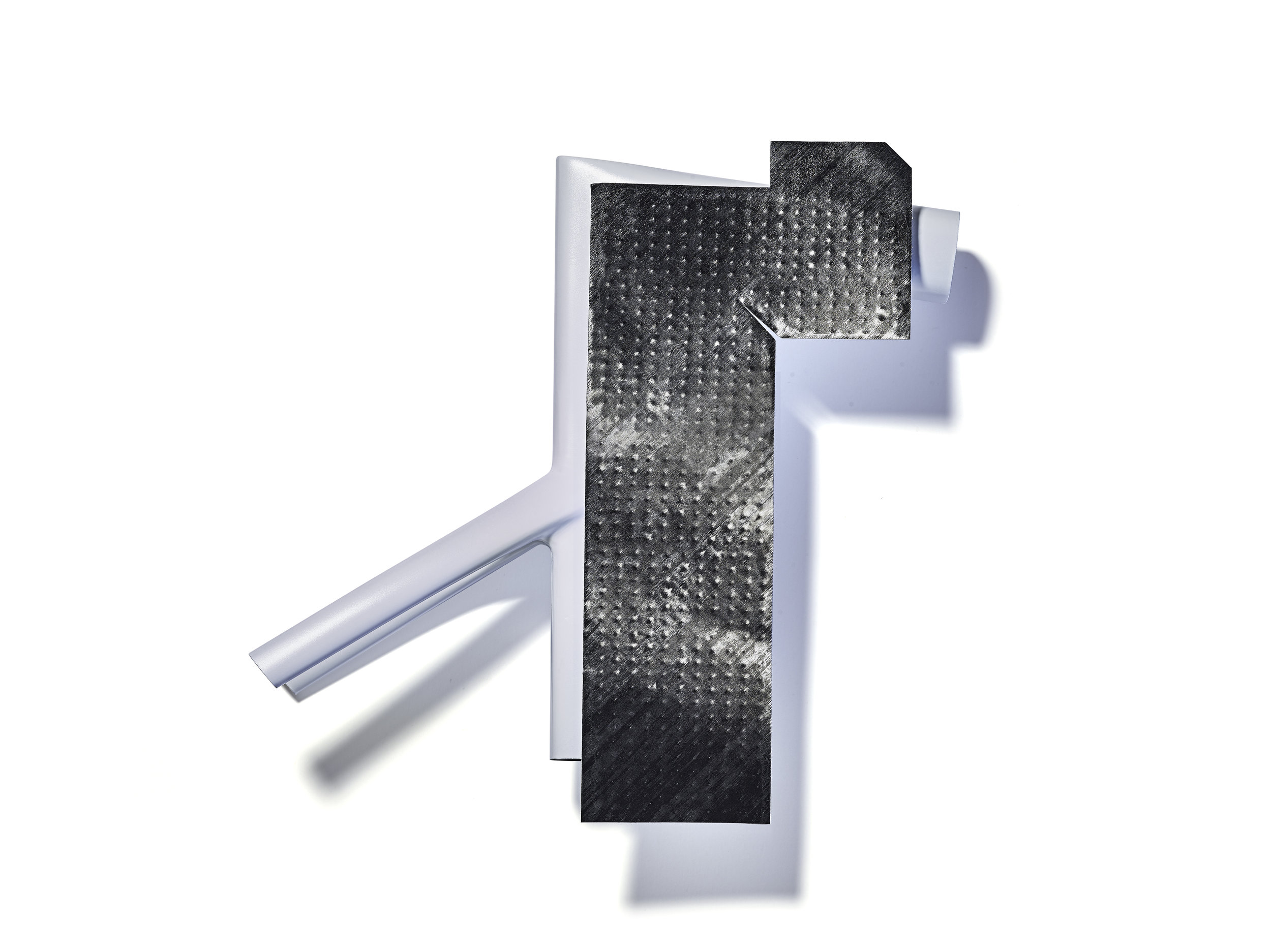

We focused on explaining the differences between small and large bicycles and showed the different approaches needed to achieve the same performance in each bike's layup.

For example, a size small (51cm) bike's head tube (where the bike's fork and handlebar connect - an area critical for the bike to feel responsive) requires additional bracing where the bike's downtube connects to the headtube. In comparison, a size large (58cm) uses two additional pieces of carbon fiber to brace the joint between the head tube and downtube and an additional piece to support the junction between the headtube and top tube. This results in the large size measuring substantially stiffer in the lab but equates to the same ride feel for the riders on the road.

We highlighted the real carbon fiber pieces placed against the location where they would live on the frame and worked to explain the reason for each adjustment. The images show the frames and placement of each reinforcing piece of carbon.

* Examples of detail photography to the right.

Retail Displays:

WinTunnel Engineered™

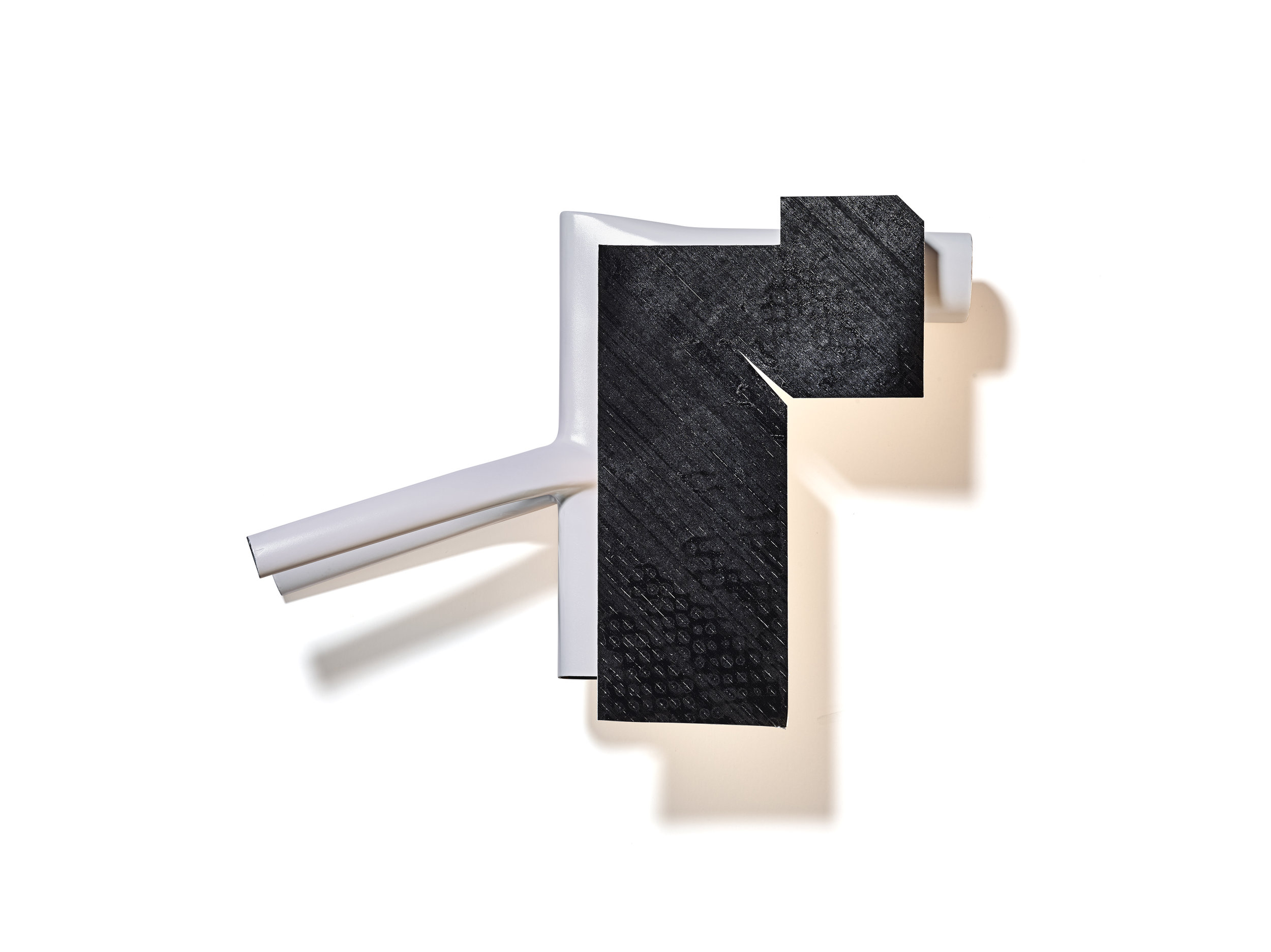

Next, we needed to highlight the development work and the aerodynamic prowess of the Tarmac. Specialized engineers have adjusted each part of the bicycle frame to interact more efficiently with the wind passing over it, thus making the bike measurable faster to the competitive consumer.

Aerodynamics are tough… you can't see the wind, so how do you know what is happening? Likewise, a BIG difference for cyclists is measured as a few seconds saved over 25miles of riding so a product that performs much better might be difficult for the user to discern immediately. This is an inches, not miles, situation.

To highlight the aerodynamic tuning, we focused on telling the story of a horizontal line drawn front to back on the bicycle frame. This line cut it in half through the forks, downtube, seat tube, and chainstays. Providing a view of the unique shapes in each of these areas. We worked to explain why they were unique and how they interact with the rest of the bicycle to improve the entire system's aerodynamics. This provided a visual way to communicate the radical shapes featured in the bike.

*To the right is an example of a print advertisement.